From the viewpoint of NYCT, the pilot project is related to the analysis of the Piper Networks UWB Rail Positioning System (RPS) as a vital component of the CBTC system (providing train positioning required for CBTC operation). In this context, the UWB RPS provides the absolute reference locations on the guideway to the OBCU which uses the data to initialize localization of the train and re-localize, as needed.

• Piper’s UWB Tags are installed in front & rear bonnets of trains.

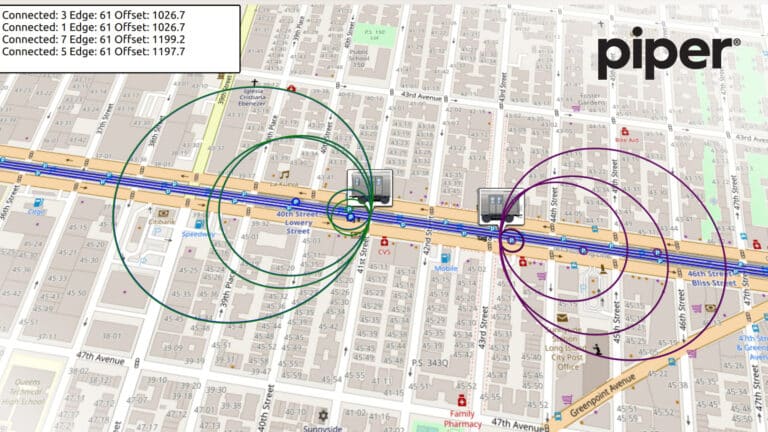

• Piper’s UWB Anchors are installed wayside on tunnel walls or on survey markers of elevated tracks. These anchors detect the tags in the trains using UWB radio signals. Each anchor detects multiple tags simultaneously and uses a Time-of-Flight algorithm to calculate the changing distance between the anchor and the tags in real-time.

• Piper Tag Controllers in the bonnet of the train capture this location data and relay the information to the Onboard Control Unit (OBCU) which in turn sends the data to the cloud.

• Our Remote Monitoring Dashboard is cloud-based and relies on a combination of network infrastructure for connectivity. In the current deployment on the Flushing 7 Line, our trains feed the dashboard through an LTE connection; revenue deployments can integrate into the MTA network for system monitoring via the RCC.

Likewise, interoperability with CBTC suppliers and UWB manufacturers will ensure that the technology will be compatible with future implementations. Piper is currently designing an interoperability specification that will help establish an industry standard for this technology.

Increasing Subway Throughput

o Ultra-precise positioning improves headways, allowing trains to run closer together and more frequently. The result is increased capacity that improves on-time performance and overall customer service.

Increasing Performance

o UWB technology can help accelerate the installation times and performance of Communications-based Train Control (CBTC). Piper is focused on reducing the delays often associated with installing new equipment and improving reliability of revenue trains.

Reducing Cost

o Piper’s positioning equipment significantly reduces the cost associated with the current generation of track bed units. Cars can be retrofitted in less than 2 hours and be ready for revenue service. As with most upgrades of trains or signaling, most of the cost is borne by the agency. Installing Piper equipment reduces the need for General Orders because the wayside equipment can be provisioned under flagging.

Interoperable

o Interoperability with CBTC suppliers and UWB manufacturers will ensure that the technology will be compatible with future implementations. Piper is currently designing an interoperability specification that will help establish an industry standard for this technology.

Improving Maintenance

o Piper’s UWB technology uses wayside instead of trackbed equipment, making it easier to install and safer to maintain. We are also able to adapt our equipment to existing infrastructure.

Once tests were completed, the Anchors, Tags, and Tag Controllers were assembled by an off-site manufacturer in a ISO 9001 certified facility under the supervision of Piper staff. After assembly, all devices were placed into installation kits with location specific brackets, power supplies, and cords. The completed Anchor kits were then shipped to NYCT’s ICC shop in Brooklyn. These kits helped streamlined the installation process as everything the installation crew needed to complete the installation was included in the box along with a reference to the installation instructions. Prior to the wayside installation, Piper conducted an on-site training class in NYC with the ICC team to step through the variety of mounting brackets, hardware, and installation types that are referenced in the UWB Wayside Anchor Installation Document.

The Piper team members were present in NYC and near the trackside during the wayside installation by ICC to answer any questions or resolve any issues quickly. Post Installation Check Out (PICO) devices were provided to verify locations. The Wayside Installation was completed in August 2019 and Piper continued to Monitor the status of the Anchors remotely. Any issues that arose were reported to the NYCT/Thales/ICC team immediately. Installation for the Carborne equipment was completed in September 2019. Once the installation was completed, shadow mode commenced and UWB ranging data collection began.

Piper anchors were installed wayside of elevated tracks by being attached to survey markers. Power supplies were also attached and connected to EDR rooms by PoE. Piper anchors were adhered to predetermined locations in tunnels by Piper’s custom developed bracketry.

Shadow mode began August 2019 and was extended for January and February 2020 in order to reach the total of 2500 UWB Ranging hours. A total of 4 trains were commissioned for the task of collecting UWB ranging data during their regular revenue service.

Piper attended weekly Workgroup meetings from the beginning of the project to discuss any issues that came up during Shadow mode. The list of Work Groups included the following:

• Construction

• Engineering

• Car Equipment

• PMO

• Service Delivery

• Technical

• Safety

• Weekly status with Thales

Miles of track on Flushing (7) Line from Hunters Point to 61st St.

187

UWB anchors installed wayside in tunnels and elevated tracks.

+4000

Hours of data have been collected.

32

UWB tags installed in the trains.

2.75

Avg. inches of accuracy for detecting train position in real-time.

9

Project was successfully completed in 9 months.

Piper was able to conduct two live demonstrations for MTA and press within 9 months of starting project. The objective of the demo was to demonstrate the functionality of the UWB- RPS system as outlined in the ICD document and the objectives for the Pilot program. Key executives and stakeholders from the NYCT team boarded the train at the 61st street station with the train following the route to 40th street and back.

Pete Tomlin, Head of Signaling, MTA provided an intro followed by Piper CEO Robert Hanczor who then did a powerpoint presentation that covered:

• Overview of Piper and UWB Technology

• Project Installation

• Live Train Positioning Demo Runs

• Live Anchor Failure Simulation Runs

• Live Work Zone Awareness Demo Runs

• Future Capabilities

The first demonstration was a success and the Piper/Thales team was invited back to NYCT to provide the second demonstration for various attendees from the press who were invited by NYCT to observe the progress of the project.

The second demonstration by the Piper Team was conducted on January 23rd, 2020. This demonstration was also a success and the turnout from the Press was impressive.